Premium Waste Management Equipment

Discover our range of high-performance machinery engineered for optimal waste processing

Our heavy-duty conveyor systems are engineered for continuous material handling in waste management facilities. Built with robust steel construction and designed for high throughput operations, these conveyors ensure smooth and efficient transportation of various waste materials throughout your processing line.

Key Features

- Heavy-duty steel construction

- Variable speed control

- Corrosion-resistant coating

- Low maintenance design

- Emergency stop systems

- Modular configuration

Specifications

| Belt Width: | 500mm - 2000mm |

| Length: | Up to 50 meters |

| Capacity: | 50-500 TPH |

| Motor Power: | 5-75 kW |

| Operating Temperature: | -20°C to +60°C |

| Material: | Mild Steel/Stainless Steel |

Applications

Waste Sorting Plants

RDF Production

Biomining Operations

Material Transport

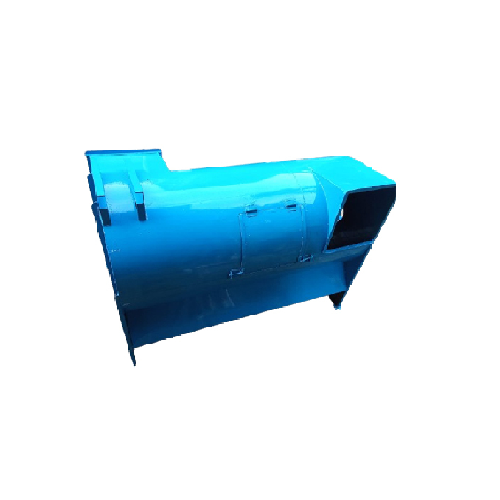

Advanced air classification technology for precise material separation based on density and aerodynamic properties. Our Air Density Separator efficiently separates light materials from heavy ones, making it ideal for waste processing, RDF production, and material recovery operations with exceptional accuracy.

Key Features

- Adjustable air flow control

- High separation efficiency

- Dust collection system

- Energy-efficient operation

- Minimal contamination

- Automated control system

Specifications

| Processing Capacity: | 50-6000TPD |

| Fan Power: | 30-200 kW |

| Air Volume: | 15,000-100,000 m³/h |

| Separation Size: | 10-300mm |

| Efficiency: | ≥95% |

| Power Supply: | 380V/50Hz |

Applications

Paper Separation

RDF Recovery

Stone Separation

High-performance rotary screening solution for efficient size classification of waste materials. Our Trommel screens feature robust construction and precision-engineered perforations for optimal separation of materials by size, essential for waste processing plants and material recovery facilities.

Key Features

- Multiple screen sizes available

- Anti-wrapping design

- Self-cleaning mechanism

- Adjustable rotation speed

- Minimal clogging

- High throughput capacity

Specifications

| Diameter: | 900mm - 3000mm |

| Length: | 8m - 11m |

| Screen Opening: | 4mm - 200mm |

| Capacity: | 20-300 TPD |

| Inclination: | 5° - 8° |

Applications

Municipal Waste

Organic Screening

C&D Waste

Organic Composting

RDF Process Plant

Our baling machines are designed for compacting recyclable materials and waste into dense, manageable bales. With robust hydraulic systems and user-friendly controls, they maximize storage and transport efficiency for paper, plastics, metals, and more.

Key Features

- High compaction ratio

- Automatic and manual operation

- Heavy-duty hydraulic system

- Easy bale ejection

- Safety interlocks

- Low maintenance

Specifications

| Bale Size: | Up to 1200 x 800 x 1000 mm |

| Capacity: | 1-10 TPD |

| Motor Power: | 7.5-30 kW |

| Operation: | Automatic/Semi-automatic |

| Material: | Mild Steel/Stainless Steel |

Applications

Recycling Centers

Paper & Cardboard

Plastic Waste

Industrial Waste

Our industrial shredders are engineered for size reduction of a wide range of waste materials. Available in single shaft and twin shaft configurations, they deliver powerful, consistent shredding for plastics, metals, e-waste, and municipal solid waste.

Key Features

- Robust cutting blades

- Low noise operation

- Overload protection

- Customizable output size

- Easy maintenance

- Heavy-duty gearbox

Specifications

| Type: | Single Shaft / Twin Shaft |

| Single Shaft Capacity: | 1-5 TPH |

| Twin Shaft Capacity: | 5-50 TPH |

| Motor Power: | 15-150 kW |

| Output Size: | 20-100 mm (adjustable) |

| Material: | Alloy Steel Blades |

Applications

Municipal Solid Waste

Plastic Shredding

E-Waste

Industrial Scrap

The Fatka Machine is designed for efficient separation and loosening of fibrous and entangled waste materials. It enhances downstream processing by breaking up clumps and improving material flow in waste management and recycling operations.

Key Features

- High-speed rotating blades

- Heavy-duty construction

- Low power consumption

- Easy integration with conveyors

- Minimal maintenance

- Safety covers and guards

Specifications

| Capacity: | 1-8 TPD |

| Rotor Speed: | 300-800 RPM |

| Motor Power: | 5-30 kW |

| Material: | Mild Steel/Stainless Steel |

| Application: | Loose & Fibrous Waste |

Applications

Waste Processing Plants

Organic Waste

Paper & Cardboard

Material Recovery